-

Notifications

You must be signed in to change notification settings - Fork 1

Example Project: Laser Staff

Pitch/idea: A staff that draws a 2m social distancing circle on the ground USING SPINNING LASER POINTERS.

I went with an Agile development methodology for making this project. This was the best fit for this project because:

-

Agile works well for small teams. I am a team of one. That's a pretty small team.

-

Having some kind of a working product quickly is important to me, another reason I went with Agile. I have two small children and I might need to make a lego rocket instead of finishing this project to a high standard. Life priorities like. At least I'll have something made to show people even if it's "unrefined".

-

Budget: My budget isn't very large so Waterfall would be best to keep costs under control.... and THAT IS WHY I'm going with Agile! Honestly, if I look at the total cost I'll be like "HELL NO I'M NOT SPENDING MY OWN MONEY ON SCHOOL STUFF!". So best go with Agile where there are hundreds of small little costs that I can conveniently never add up in my head until the VISA bill comes in later, then I can negotiate with Rachel and she can buy some stuff on Amazon too so I don't feel so guilty. I'll just say something about it being for my favourite students who are so wonderful etc blah blah.

I looked up other people doing this. I think I have everything I need to make something like this. I'm not sure about doing two lasers or one.

I needed something that could spin a laser so I used a 3V motor. I started off actually not spinning the laser but spinning a much smaller mirror on a piece of an old camera tripod.

I made the thing out of metal stand with the spinning mirror.

I did a FUNCIONAL TEST of what I'd made. Yeah the mirror was rubbish because the reflected laser was too dim and blurry and would some times be blocked by the frame of the holder.

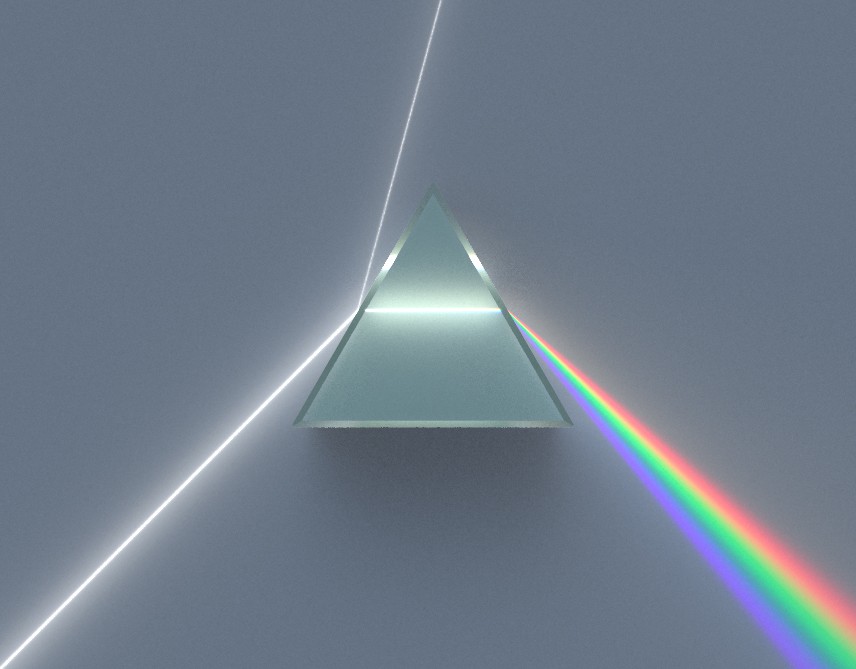

I looked up mirrors and turns out they only reflect about 60% of the light. Apparently, this is why people use prisms and glass instead ina submarine periscope.

I designed a new version that uses a small glass prism instead.

I made the prism prototype.

I did a FUNCIONAL TEST of what I'd made. It's a bit better but it's still being blocked by the frame. Also, it's bloody terrifying to stand anywhere near. The sound of that prism spinning is disconcerting, to say the least. A sharp-edged block of glass spinning at 3000 rpm, only held on by some hot glue...I think a need a new way of doing this.

Back to the drawing board!

(there was kind of a version 2.5 where I added a resistor to slow the spinning down but I wasn't happy with the brightness still)

This time I'm going for a laser. After having some issues with vibration, I've decided to go with two lasers for balance. Also my glue work will never get it quite evenly balanced so I'm going to 3D print a mount for the lasers using Adobe 360 Fusion and my Junior Cert Tech Graphics SKILLZ.

I removed as much weight as possible but gutting out holes in the centre.

Also, it now looks completely badass.

I also designed and 3D printed a battery pack for 2 x AAA batteries.

The holes needed to be a big bigger so I had to use a file to widen them. After that the lasers fit just fine. I printed out a 3D laser pen clip so that I didn't have to hold down the buttons.

I did a SYSTEM TEST of what I'd made by bringing it into school and walking about. It works fine yea but I've no idea how to put this on a hat. So I duct-taped it on to a staff. The two AAA batteries are not really powerful enough to spin it when you're moving and there's friction or wind resistance. I need a bigger battery pack.

Reflecting on the last design, I reckon the whole thing could be reduced in size and simplicity. If I can reduce the size, maybe the motor won't need to work so hard. What's really surprising is the friction and wind resistance. You forget that the faster the thing spings, the more drag. Actually it's worse than that. It seems to increase the drag force with the square of the speed. So double the speed, quadruple the force needed to overcome air resistance.

I went back to something that is more like the original paint diagram.

I ended up going with the original because it looked cooler.

I went back to something that is more like the original paint diagram.